Industrial control and factory automation is the convergence of smart mechanical technologies with information technology. Organizations across process as well as discrete industries use industrial control and factory automation solutions to improve operational efficiency and minimize or reduce human intervention. The market is mainly driven by the adoption of IoT and advancement in M2M communication technology, as they help manufacturers to better analyze the real-time data and act accordingly for predictive maintenance. The adoption of advanced manufacturing practices in the U.S. and a few countries in Europe and growing demand of robotics and other automation technologies in emerging economies such as China is expected to create growth opportunities for the industrial control and factory automation market in near future.

The increasing end user investments in the field of monitoring, visualization, and control equipment, enhances the global SCADA market growth and transform into an indispensable part of industrial automation.

However, the future of factories and enterprises depends largely on how the next generation SCADA is designed and deployed across complex industrial applications. The adoption SCADA is increasing with the emergence of smart manufacturing. In addition, there is a paradigm shift towards application development that helps in better control and communication among different devices. Such apps are enabling operators to remotely monitor and modify important data of key parameters such as pressure, temperature, and flow among others, via smartphones and tablets. One such app is ProSoft i-View introduced by ProSoft Technology Inc. (U.S.), which provides real-time remote SCADA and process control capability for plant operators. The product works with the Ethernet/IP or Modbus TCP/IP networks and can display live process control values in a list format, including user-established variance allowances with realtime alarms and notifications.

The technological developments in SCADA system and its deployment through integration of other solutions enabled the manufacturers to have more opportunities. This emerging trend is increasingly becoming evident with globalized service support and cost factors playing a crucial role. The key players operating in this segment include ABB Limited (Switzerland), Rockwell Automation Inc. (U.S.), and Schneider Electric (France), among others

The Americas accounted for the largest share of the industrial control and factory automation market in 2017. This large share can be attributed to the presence of major vendors of industrial control and factory automation products and the adoption of these products by a large number of end users in the region. The market in Asia-Pacific is expected to grow at the highest CAGR from 2017 to 2023, and accounted for a share of major of the industrial control and factory automation market in 2017. The growth of the industrial control and factory automation market in Asia-Pacific is driven by the growing industrial sectors in China and India. Furthermore, the adoption of factory automation products in China is increasing, as a large number companies operational in the automotive sector have set up their manufacturing plants in the country. Factory automation solutions are being rapidly adopted by several manufacturers in the automotive sector for faster production process, improved operational efficiency, and reduced of complexity of the production process.

Major companies operational in the industrial control and factory automation market include Siemens AG (Germany), Emerson Electric Co. (U.S.), General Electric Company (U.S.), Schneider Electric SE (France), Honeywell International, Inc. (U.S.), Rockwell Automation, Inc. (U.S.), Yokogawa Electric Corporation (Japan), Mitsubishi Electric Corporation (Japan), and ABB Ltd. (Switzerland)Smart Home technology moving towards connected systems from connected devices.

1 Introduction

1.1 Goal & Objective

1.2 Study Scope

1.3 Assumptions and Limitations

1.4 Stakeholders/ Intended Audience

1.5 Research Methodology

2 Executive Summary

3 Market Outlook

3.1 Introduction

3.2 Current & Future Outlook

3.3 DROC

3.3.1 Drivers

3.3.2 Restraints

3.3.3 Opportunities

3.3.4 Challenges

3.4 Value Chain & Ecosystem

4 Global Industrial Automation Market: By Type

4.1 Introduction

4.2 Distributed Control System ( DCS )

4.2.1 Market Size & Forecasts, 2018-2023

4.3 Programmable Logic Control system (PLC )

4.3.1 Market Size & Forecasts, 2018-2023

4.4 Machine Vision System

4.4.1 Market Size & Forecasts, 2018-2023

4.5 Human Machine Interface

4.5.1 Market Size & Forecasts, 2018-2023

4.6 Supervisory Control and Data Acquisition ( SCADA )

4.6.1 Market Size & Forecasts, 2018-2023

4.7 Manufacturing Execution System ( MES )

4.7.1 Market Size & Forecasts, 2018-2023

4.8 Product Lifecycle Management ( PLM)

4.8.1 Market Size & Forecasts, 2018-2023

4.9 Electronic Control Units

4.9.1 Market Size & Forecasts, 2018-2023

4.1 Others

4.10.1 Market Size & Forecasts, 2018-2023

5 Automation Market, By Discrete Industries

5.1 Introduction

5.2 Automotive

5.2.1 Market Size & Forecasts, 2018-2023

5.3 Marine

5.3.1 Market Size & Forecasts, 2018-2023

5.4 Food, Beverage & Tobacco machinery

5.4.1 Market Size & Forecasts, 2018-2023

5.5 Paper and Pulp

5.5.1 Market Size & Forecasts, 2018-2023

5.6 Semiconductor machinery

5.6.1 Market Size & Forecasts, 2018-2023

5.7 Textile machinery

5.7.1 Market Size & Forecasts, 2018-2023

5.8 Rubber and Plastics machinery

5.8.1 Market Size & Forecasts, 2018-2023

5.9 Robotics

5.9.1 Market Size & Forecasts, 2018-2023

5.10 Others

5.10.1 Market Size & Forecasts, 2018-2023

6 Automation Market, By Process Industries

6.1 Introduction

6.2 Oil and Gas

6.2.1 Market Size & Forecasts, 2018-2023

6.2.2 Upstream

6.2.3 Midstream

6.2.4 Downstream

6.3 Water and Waste water

6.3.1 Market Size & Forecasts, 2018-2023

6.4 Power Generation

6.4.1 Market Size & Forecasts, 2018-2023

6.5 Chemicals and Pharmaceuticals

6.5.1 Market Size & Forecasts, 2018-2023

6.6 Metal and Mining

6.6.1 Market Size & Forecasts, 2018-2023

6.7 Cement , Glass & Ceramics

6.7.1 Market Size & Forecasts, 2018-2023

6.8 Others

6.8.1 Market Size & Forecasts, 2018-2023

7 Automation Market, By Region

7.1 North America

7.1.1 North America Market Size, By Country 2018-2023

7.1.2 North America Market Size, By By Type 2018-2023

7.1.3 North America Market Size, By By Industry 2018-2023

U.S.

U.S. Market Size, By By Type 2018-2023

U.S. Market Size, By By Industry 2018-2023

Canada

Canada Market Size, By By Type 2018-2023

Canada Market Size, By By Industry 2018-2023

Mexico

Mexico Market Size, By By Type 2018-2023

Mexico Market Size, By By Industry 2018-2023

6.2 Europe

7.2.1 Europe Market Size, By Country 2018-2023

7.2.2 Europe Market Size, By By Type 2018-2023

7.2.3 Europe Market Size, By By Industry 2018-2023

Germany

Germany Market Size, By By Type 2018-2023

Germany Market Size, By By Industry 2018-2023

Italy

Italy Market Size, By By Type 2018-2023

Italy Market Size, By By Industry 2018-2023

France

France Market Size, By By Type 2018-2023

France Market Size, By By Industry 2018-2023

UK

UK Market Size, By By Type 2018-2023

UK Market Size, By By Industry 2018-2023

Spain

Spain Market Size, By By Type 2018-2023

Spain Market Size, By By Industry 2018-2023

Rest of Europe

Rest Of Europe Market Size, By By Type 2018-2023

Rest Of Europe Market Size, By By Industry 2018-2023

7.3 Asia-Pacific

7.3.1 Asia-Pacific Market Size, By Country 2018-2023

7.3.2 Asia-Pacific Market Size, By By Type 2018-2023

7.3.3 Asia-Pacific Market Size, By By Industry 2018-2023

China

China Market Size, By By Type 2018-2023

China Market Size, By By Industry 2018-20223

India

India Market Size, By By Type 2018-2023

India Market Size, By By Industry 2018-2023

Japan

Japan Market Size, By By Type 2018-2023

Japan Market Size, By By Industry 2018-2023

Australia

Australia Market Size, By By Type 2018-2023

Australia Market Size, By By Industry 2018-2023

Rest of APAC

Rest Of APAC Market Size, By By Type 2018-2023

Rest of APACMarket Size, By By Industry 2018-20223

7.4 Middle East & Africa

7.4.1 Middle East & Africa Market Size, By By Type 2018-2023

7.4.2 Middle East & Africa Market Size, By By Industry 2018-2023

7.5 South America

7.5.1 South America Market Size, By By Type 2018-2023

7.5.2 South America Market Size, By By Industry 2018-2023

Supply Market Analysis

8.1 Strategic Benchmarking

8.2 Market Share Analysis

8.3 Key Players

8.3.1 ABB

8.3.2 Emerson

8.3.3 Rockwell Automation

8.3.4 Siemens

8.3.5 General Electric

8.3.6 Schneider

8.3.7 Yokogawa

8.3.8 Omron

8.3.9 Mitsubishi

8.3.10 Honeywell & Others

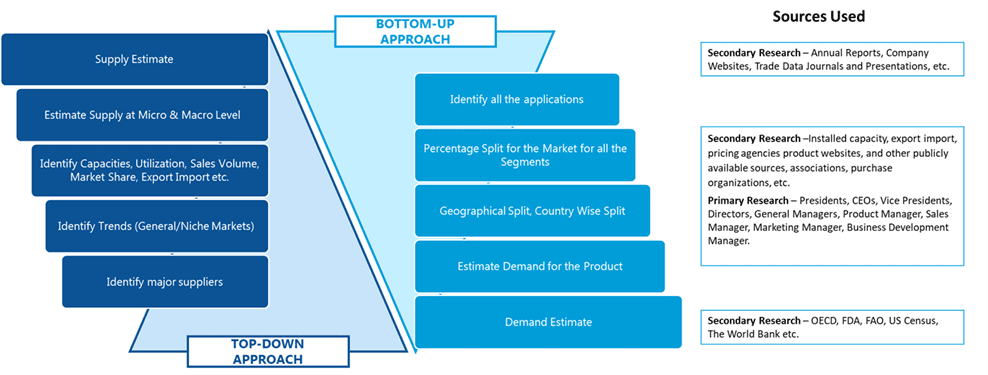

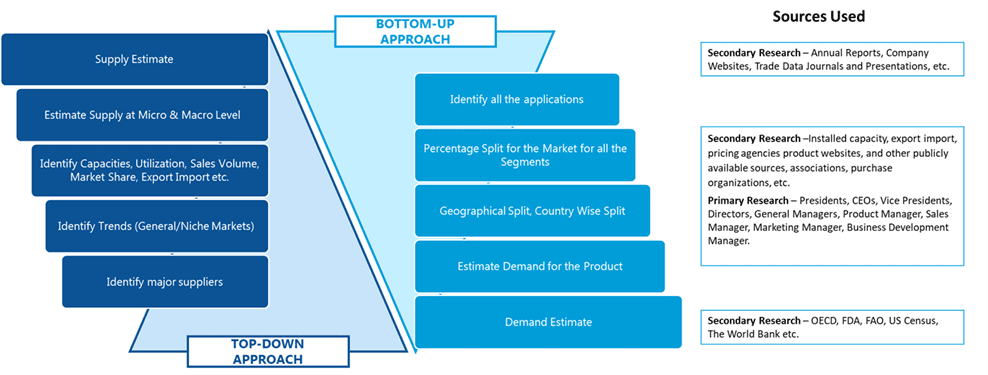

SDMR employs a three way data triangulation approach to arrive at market estimates. We use primary research, secondary research and data triangulation by top down and bottom up approach

Secondary Research:

Our research methodology involves in-depth desk research using various secondary sources. Data is gathered from association/government publications/databases, company websites, press releases, annual reports/presentations/sec filings, technical papers, journals, research papers, magazines, conferences, tradeshows, and blogs.

Key Data Points through secondary research-

Macro-economic data points

Import Export data

Identification of major market trends across various applications

Primary understanding of the industry for both the regions

Competitors analysis for the production capacities, key production sites, competitive landscape

Key customers

Production Capacity

Pricing Scenario

Cost Margin Analysis

Key Data Points through primary research-

Major factors driving the market and its end application markets

Comparative analysis and customer analysis

Regional presence

Collaborations or tie-ups

Annual Production, and sales

Profit Margins

Average Selling Price

Data Triangulation:

Data triangulation is done using top down and bottom approaches. However, to develop accurate market sizing estimations, both the methodologies are used to accurately arrive at the market size. Insert Image