The boron nitride market will reach 8.6 million tons by 2023 growing at a CAGR of 5.0 from 2018-2023. Boron Nitride and boron carbide are the major compounds. Boron Nitride market possess various high thermal conductivity, low thermal expansion, good thermal shock resistance, high electrical resistance, and high electrical resistance. The major factors contributing towards the growth are increasing demand from coating, mold industry, electrical industry, ceramics, and industrial

In 2017, North America captured the largest share in boron nitride the market where as Asia Pacific will grow at a highest growth rate of 5.3% from 2018-2023. IN 2017, USA captured the largest market share in the boron nitride market. Emerging economies such as Middle East & South America will experience a CAGR % mainly due to growing industrialization, expansion of manufacturing facilities and stable economic growth.

In 2017, the coating application captured the major market share in the boron nitride market. The applications of boron nitride are coating and mold/die release, electrical insulation, industrial lubrication, composites, cosmetics, lubricant food grade, paints, thermal spray and other. In coatings, they are mainly used in molds, troughs, furnace linings and light-metal applications. In aerospace, it is used in thermal spray coatings, in turbine engines, dynamic friction materials, and erosion resistant coatings.

The company are focusing on expanding their production capacity all the major applications. The major players in the boron nitride powder market are 3M Technical Ceramics / ESK Ceramics, Accuratus Corporation, American Elements, Aremco Products Inc., Atlantic Equipment Engineers, Bayvile Chemical Supply, Bent Tree Industries, Boron Compounds Limited, BORTEK, Ceramic Substrates and Components Limited, Chengdu Huarui Industrial Limited, Dengchang Chemical Engineering Institute, Dangong Chemical Engineering Institute (DCEI), Denka Denki Kagaya Kogyo Kabushiki Kaisha, GoodFellow, H.C.Starck GmbH, Henze Boron Nitride Products AG, JSC ‘’Zaporozhsky Abrasivny Combinat’’, Kennametal, Kolortek Co., Ltd., Kurt J.Lesker Company and Others

1. Introduction

2. Executive Summary

3. Boron Nitride Powder & Hot Pressed Shapes Overview

3.1. Introduction

3.2. Key characteristics

3.3. Key benefits

3.4. Production process

3.5. Property comparison

3.6. Product life cycle analysis

3.7. Environmental impact

3.8. Value Chain analysis

3.9. Porter five forces analysis

3.10. DROC

3.10.1. Drivers

3.10.2. Restraints

3.10.3. Opportunities

3.10.4. Challenges

4. Boron Nitride Powder

4.1. Market analysis by Region

4.1.1. Current market for the year 2016

4.1.1.1. North America

4.1.1.2. Western Europe

4.1.1.3. Eastern Europe

4.1.1.4. Asia

4.1.1.5. Rest of the world

4.1.2. Forecast from 2017 to 2022

4.1.2.1. North America

4.1.2.2. Western Europe

4.1.2.3. Eastern Europe

4.1.2.4. Asia

4.1.2.5. Rest of the world

4.2. Market analysis by segments

4.2.1. Coating and mold / die release

4.2.1.1. Introduction

4.2.1.2. Application details

4.2.1.3. Current Market scenario for 2016

4.2.1.4. Forecast from 2017 to 2022

4.2.1.5. Key growth drivers

4.2.1.6. Key constraints for growth

4.2.2. Electrical Insulation

4.2.2.1. Introduction

4.2.2.2. Application details

4.2.2.3. Current Market scenario for 2016

4.2.2.4. Forecast from 2017 to 2022

4.2.2.5. Key growth drivers

4.2.2.6. Key constraints for growth

4.2.3. Industrial Lubrication

4.2.3.1. Introduction

4.2.3.2. Application details

4.2.3.3. Current Market scenario for 2016

4.2.3.4. Forecast from 2017 to 2022

4.2.3.5. Key growth drivers

4.2.3.6. Key constraints for growth

4.2.4. Composites

4.2.4.1. Introduction

4.2.4.2. Application details

4.2.4.3. Current Market scenario for 2016

4.2.4.4. Forecast from 2017 to 2022

4.2.4.5. Key growth drivers

4.2.4.6. Key constraints for growth

4.2.5. Cosmetics

4.2.5.1. Introduction

4.2.5.2. Application details

4.2.5.3. Current Market scenario for 2016

4.2.5.4. Forecast from 2017 to 2022

4.2.5.5. Key growth drivers

4.2.5.6. Key constraints for growth

4.2.6. Lubrication food grade

4.2.6.1. Introduction

4.2.6.2. Application details

4.2.6.3. Current Market scenario for 2016

4.2.6.4. Forecast from 2017 to 2022

4.2.6.5. Key growth drivers

4.2.6.6. Key constraints for growth

4.2.7. Paints

4.2.7.1. Introduction

4.2.7.2. Application details

4.2.7.3. Current Market scenario for 2016

4.2.7.4. Forecast from 2017 to 2022

4.2.7.5. Key growth drivers

4.2.7.6. Key constraints for growth

4.2.8. Thermal spray

4.2.8.1. Introduction

4.2.8.2. Application details

4.2.8.3. Current Market scenario for 2016

4.2.8.4. Forecast from 2017 to 2022

4.2.8.5. Key growth drivers

4.2.8.6. Key constraints for growth

4.2.9. Boron Nitride Powder pricing analysis

4.2.9.1. Current price by region

4.2.9.2. Expected price in next 5 years

4.2.9.3. Price drivers

4.2.9.4. Constraints

5. Boron Nitride Hot Pressed Shapes

5.1. Market Analysis by Region

5.1.1. Current market for the year 2016

5.1.1.1. North America

5.1.1.2. Western Europe

5.1.1.3. Eastern Europe

5.1.1.4. Asia

5.1.1.5. Rest of the world

5.1.2. Forecast from 2017 to 2022

5.1.2.1. North America

5.1.2.2. Western Europe

5.1.2.3. Eastern Europe

5.1.2.4. Asia

5.1.2.5. Rest of the world

5.2. Market Analysis by Segments

5.2.1. High temperature applications

5.2.1.1. Introduction

5.2.1.2. Application details

5.2.1.3. Current Market scenario for 2016

5.2.1.4. Forecast from 2017 to 2022

5.2.1.5. Key growth drivers

5.2.1.6. Key constraints for growth

5.2.2. Thermal management for electronic devices

5.2.2.1. Introduction

5.2.2.2. Application details

5.2.2.3. Current Market scenario for 2016

5.2.2.4. Forecast from 2017 to 2022

5.2.2.5. Key growth drivers

5.2.2.6. Key constraints for growth

5.2.3. Molten metal handling

5.2.3.1. Introduction

5.2.3.2. Application details

5.2.3.3. Current Market scenario for 2016

5.2.3.4. Forecast from 2017 to 2022

5.2.3.5. Key growth drivers

5.2.3.6. Key constraints for growth

5.2.4. Others

5.2.4.1. Introduction

5.2.4.2. Application details

5.2.4.3. Current Market scenario for 2016

5.2.4.4. Forecast from 2017 to 2022

5.2.4.5. Key growth drivers

5.2.4.6. Key constraints for growth

5.3. Boron Nitride Hot Pressed Shapes by binder type

5.3.1. Boric oxide

5.3.2. Diffusion Bonded

5.3.3. Calcium Borate

5.4. Boron Nitride Powder Hot Pressed Shapes pricing analysis

5.4.1. Current price by region

5.4.2. Expected price in next 5 years

5.4.3. Price drivers

5.4.4. Constraints

6. Competitive Benchmarking

6.1. Company Profile-Details

6.1.1. Company introduction

6.1.2. SWOT analysis in terms of Boron Nitride

6.1.3. Financials*

6.1.4. Employee and R&D details**

6.1.5. Products offerings

6.1.6. Plant locations

6.1.7. Installed capacity and utilisation rates

6.1.7.1. Capacity expansion plans

6.1.7.2. Capacity shares

6.1.7.3. Market shares

6.1.8. Strategic imperatives

6.1.9. Export destinations

6.1.10. Key Players

6.1.10.1. 3M Technical Ceramics / ESK Ceramics

6.1.10.2. Accuratus Corporation

6.1.10.3. American Elements

6.1.10.4. Aremco Products Inc.

6.1.10.5. Atlantic Equipment Engineers

6.1.10.6. Bayvile Chemical Supply

6.1.10.7. Bent Tree Industries

6.1.10.8. Boron Compounds Limited

6.1.10.9. BORTEK

6.1.10.10. Ceramic Substrates and Components Limited

6.1.10.11. Chengdu Huarui Industrial Limited

6.1.10.12. Dengchang Chemical Engineering Institute

6.1.10.13. Dangong Chemical Engineering Institute (DCEI)

6.1.10.14. Denka Denki Kagaya Kogyo Kabushiki Kaisha

6.1.10.15. GoodFellow

6.1.10.16. H.C.Starck GmbH

6.1.10.17. Henze Boron Nitride Products AG

6.1.10.18. JSC ‘’Zaporozhsky Abrasivny Combinat’’

6.1.10.19. Kennametal

6.1.10.20. Kolortek Co., Ltd.

6.1.10.21. Kurt J.Lesker Company

6.1.10.22. Lisoning Pengda Technology Co., Ltd

6.1.10.23. Lower friction/M.K. IMPEX CORP

6.1.10.24. Mizushima Ferroalloy Co., Ltd.

6.1.10.25. Momentive Performance Materials Inc.

6.1.10.26. National Nitride Technologies Co., Ltd. & Others

We have profiled around 50+ players.

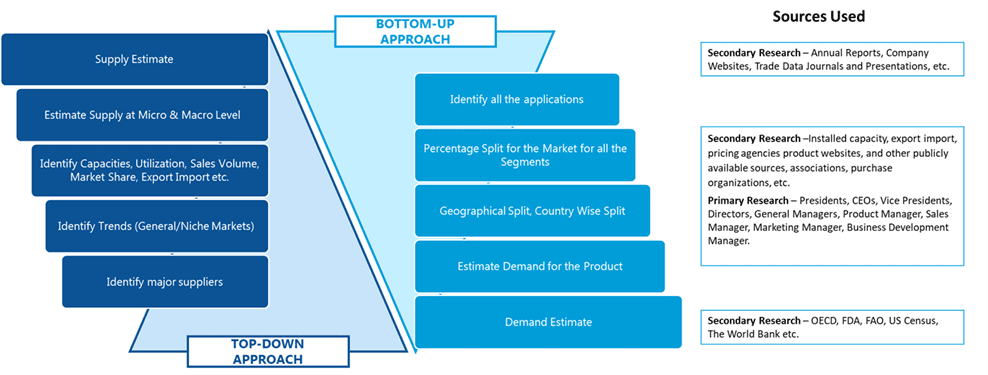

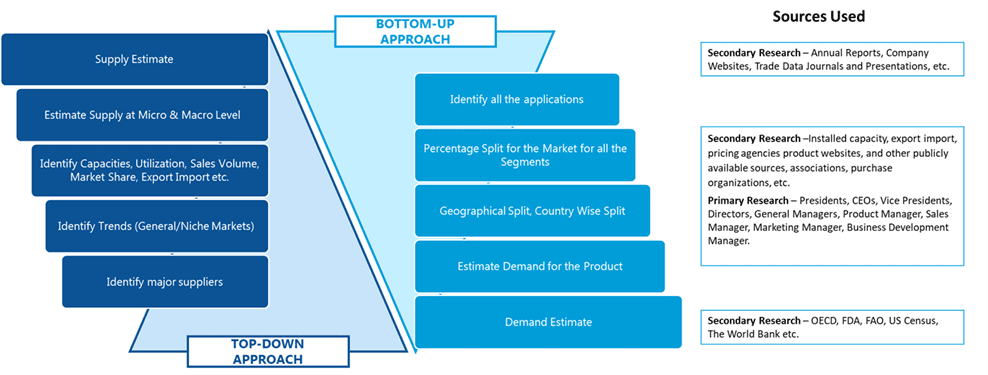

SDMR employs a three way data triangulation approach to arrive at market estimates. We use primary research, secondary research and data triangulation by top down and bottom up approach

Secondary Research:

Our research methodology involves in-depth desk research using various secondary sources. Data is gathered from association/government publications/databases, company websites, press releases, annual reports/presentations/sec filings, technical papers, journals, research papers, magazines, conferences, tradeshows, and blogs.

Key Data Points through secondary research-

Macro-economic data points

Import Export data

Identification of major market trends across various applications

Primary understanding of the industry for both the regions

Competitors analysis for the production capacities, key production sites, competitive landscape

Key customers

Production Capacity

Pricing Scenario

Cost Margin Analysis

Key Data Points through primary research-

Major factors driving the market and its end application markets

Comparative analysis and customer analysis

Regional presence

Collaborations or tie-ups

Annual Production, and sales

Profit Margins

Average Selling Price

Data Triangulation:

Data triangulation is done using top down and bottom approaches. However, to develop accurate market sizing estimations, both the methodologies are used to accurately arrive at the market size. Insert Image